2007-2010

Preparing to Retire ReWIRE

Woodworking had been a casual hobby ever since wood shop in high school, but I’d never really had the space it required until we moved to the farm. As retirement approached, I got deeply involved in designing a woodworking shop inside a corner of the barn. True to form, I made mechanical and electrical drawings of everything before I pounded the first nail, and researched the advantages of every machine tool before buying it.

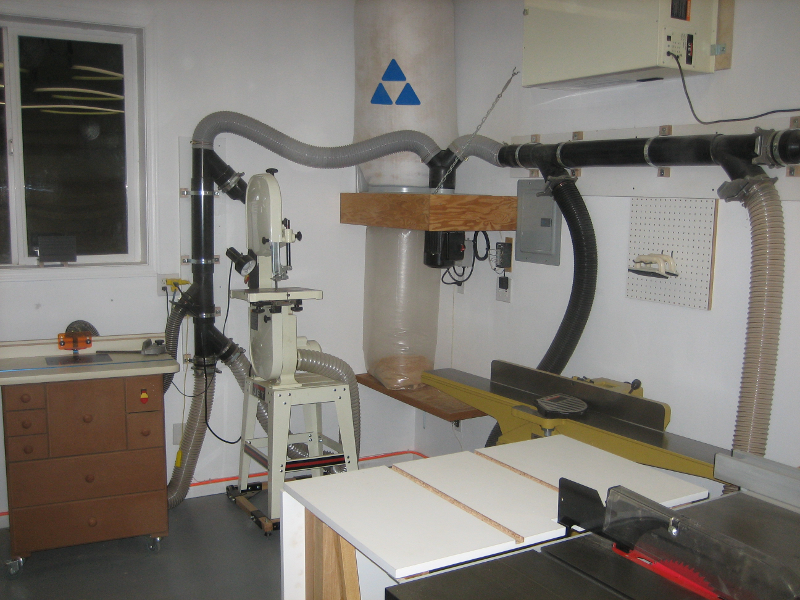

Building the shop was my first real carpentry project, and I had to learn as I went. The electrical part was easier: ample 220V power, heat and A/C, and a vacuum sawdust collection system that activated automatically with the tools. The pictures below show some of the features of the shop.

For raw woodworking material, I hoped to draw upon our orchard of Black Walnut trees. They were 80 years old and a couple of them fell over each year. After cutting the trunks to 3-4 foot lengths, I hauled them to a shed for drying, and rigged up a home-built milling sled for my bandsaw. While I was able to produce some boards, the over-aged wood was full of internal cracks and warped badly as it dried. It was a disappointment but a valuable learning experience.