DIY assistive technology for assembling miniaturized electronic prototypes

2020

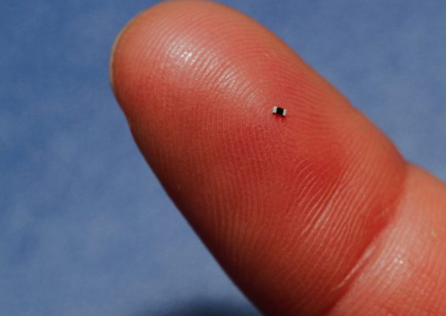

When I first started tinkering with electronics in the mid-20th century, most circuits used vacuum tubes. Over the 60 years since then, I’ve been privileged to witness the stunning progress in miniaturization, first with transistors, then basic integrated circuits, all the way to highly complex chips the size of your thumbnail with billions of transistors inside. To keep pace, small passive components — resistors and capacitors — shrank too. To build a prototype of a wearable device with a small size and weight, you have to be able to assemble these minuscule chips and components.

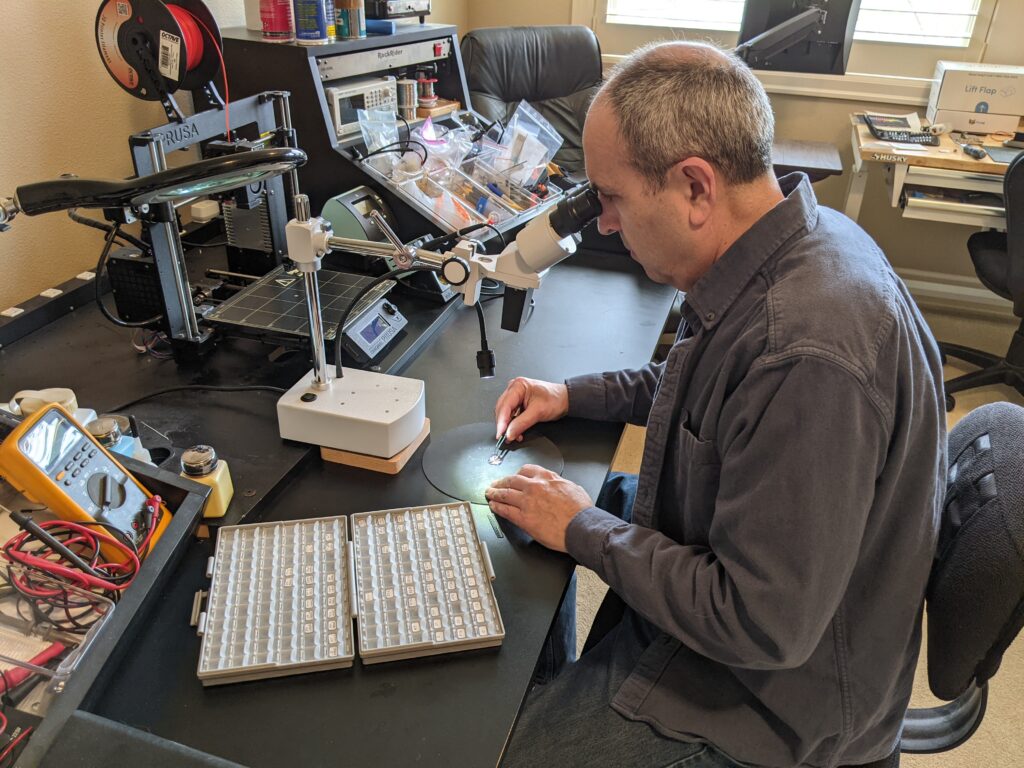

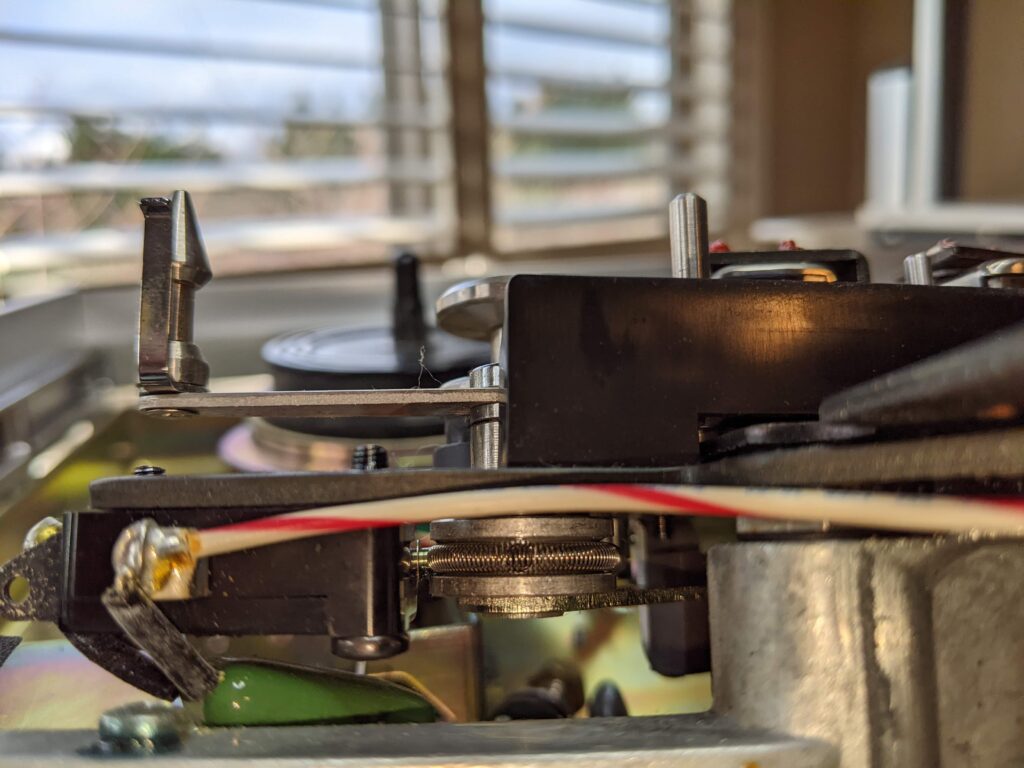

To assemble a circuit, I apply solder paste to pads on a printed circuit board using a laser-cut stencil. A boom microscope provides adequate magnification to see the parts, but the final step requires using a hand-held forceps to pick up and place the tiny components in exactly the right positions on the PC board. By the time I reached 70 years of age, the parts had shrunk to 0.040 x 0.020 inches size, with placement tolerances of 5 thousandths of an inch. And I found I could no longer grip, maneuver, and release the part from the forceps with the rock-steadiness required. Unwilling to give up, I hatched a DIY solution that restored my ability to place components at this new level of precision. More details are available after the photographs.

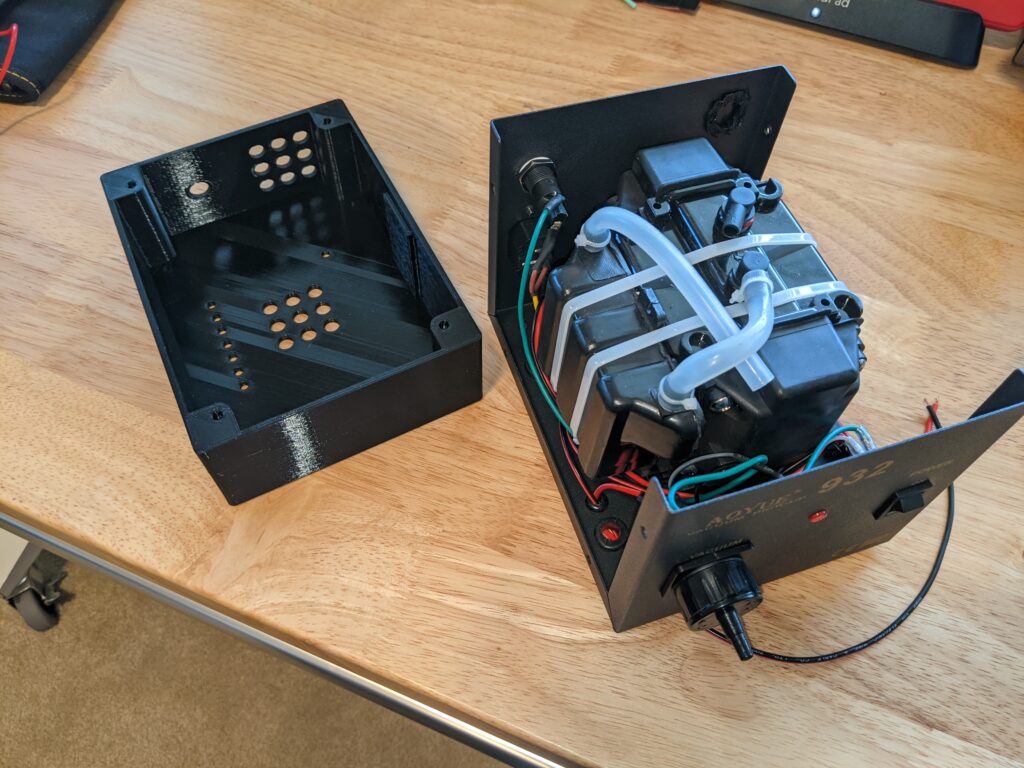

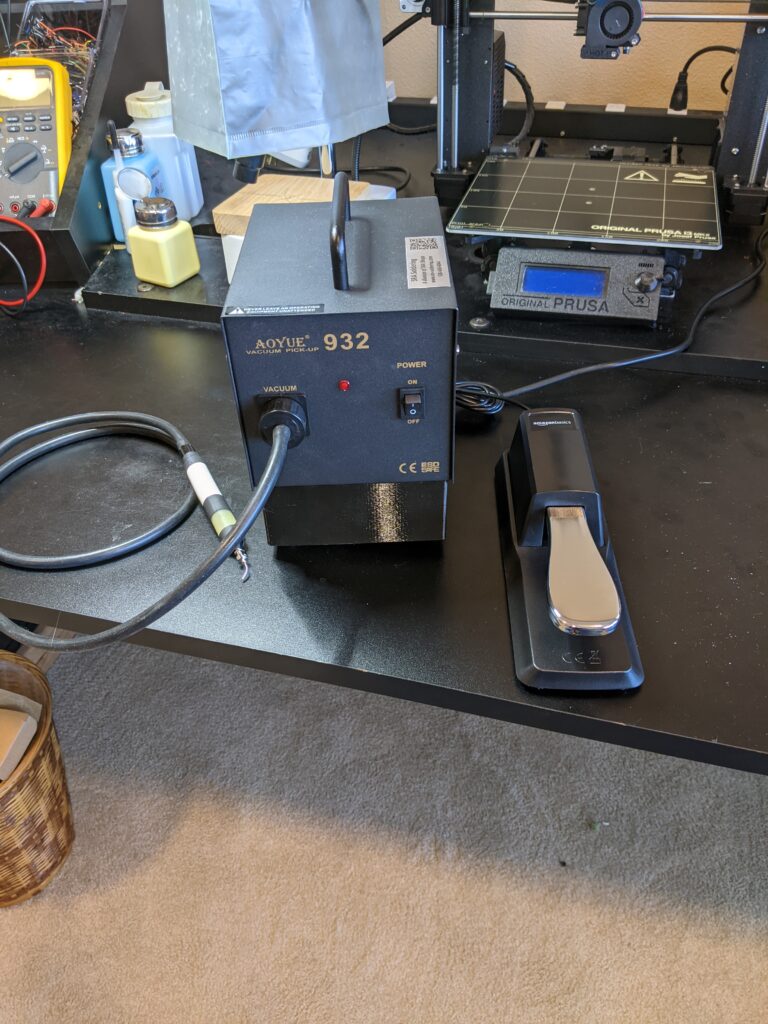

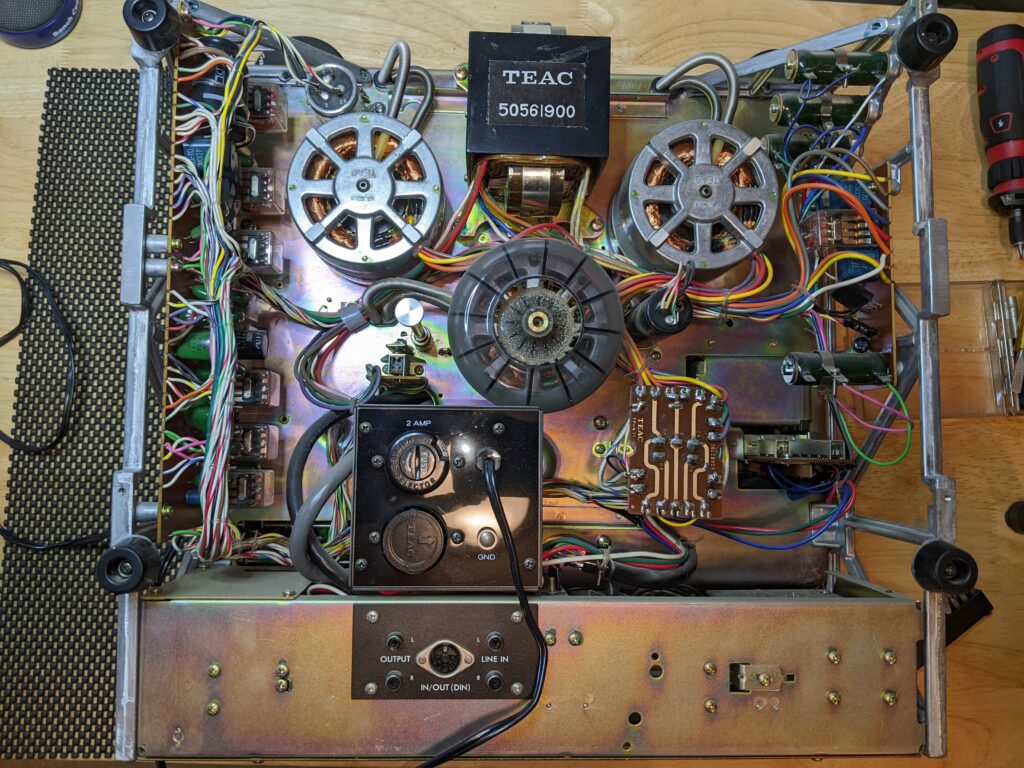

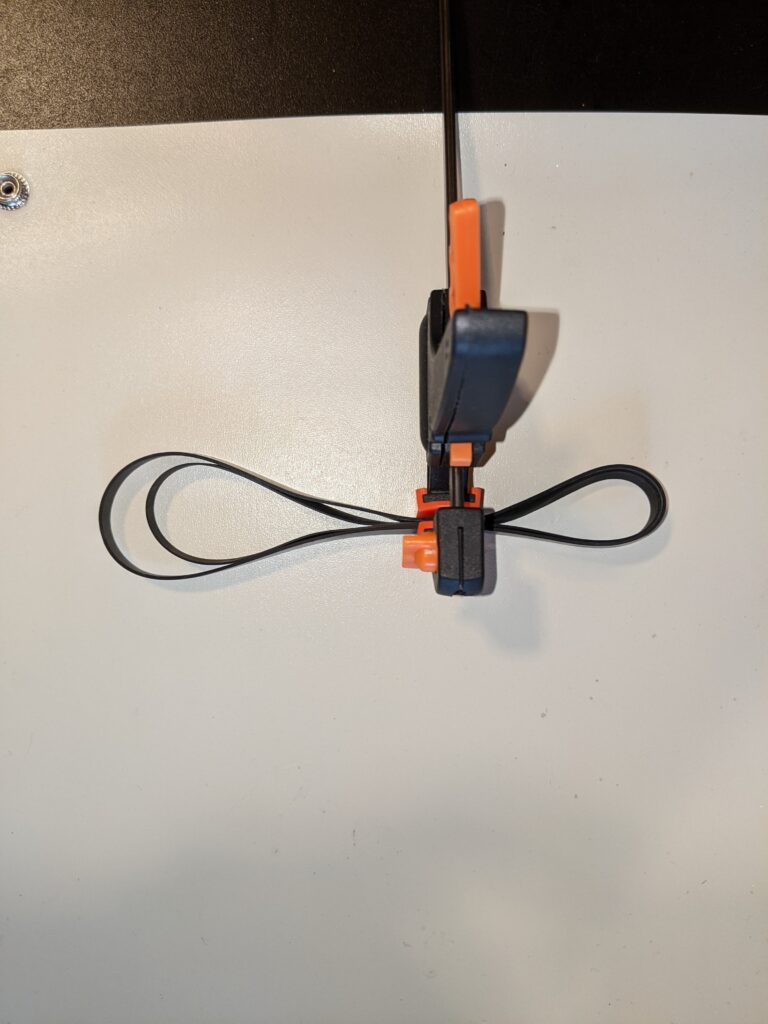

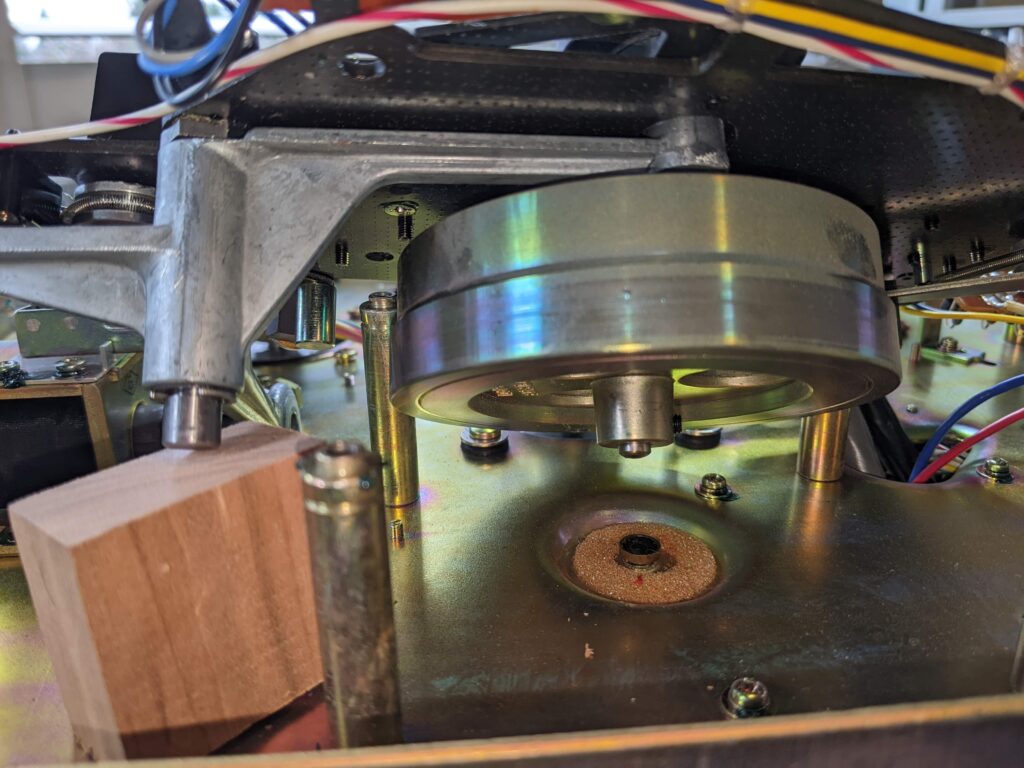

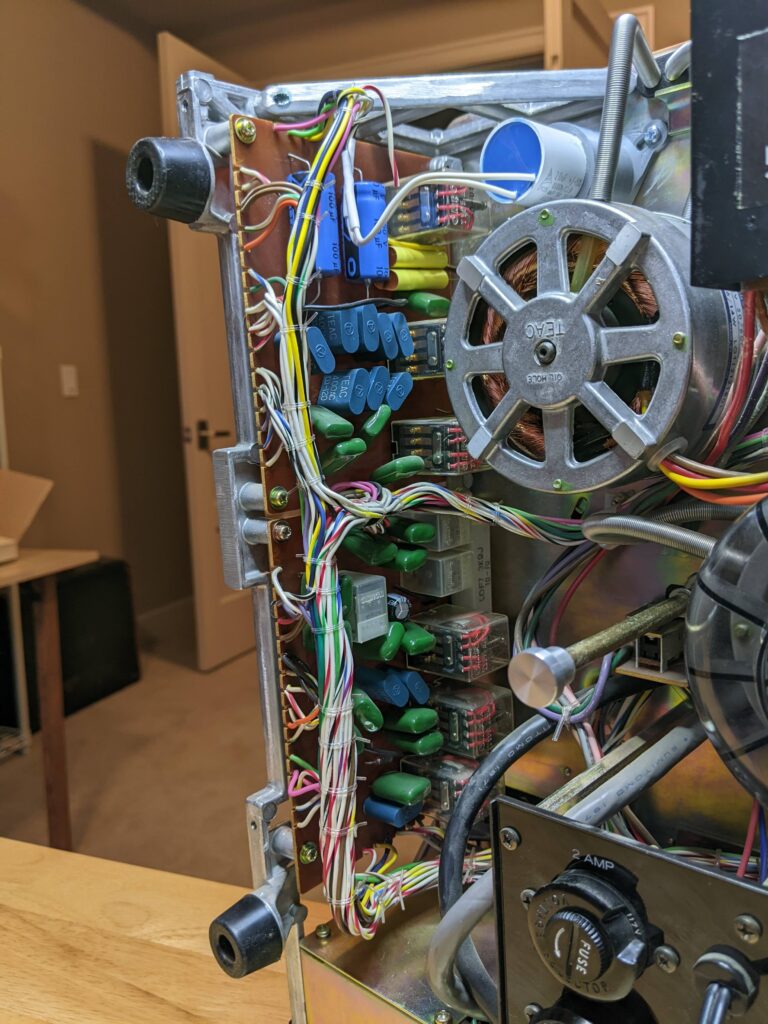

The first problem was one of crosstalk between two manual processes: moving the part into position over the PC board, and releasing pressure on the forceps at the right moment. The solution was to use a vacuum pick-up device instead of a forceps, and to reassign the function of releasing the vacuum to a foot pedal instead of my hand. From the photos, you’ll see how I started with an inexpensive vacuum pump, then added solenoid valves and associated circuitry to allow foot-pedal control of the vacuum.

The second problem was that of tremor. With aging some neurons conduct impulses more slowly or even stop functioning, and a servomechanism with excessive delay in its control loop will overshoot and oscillate — and that causes tremor. The solution was to add a stabilizing fixture, with a fulcrum close to the PC board, and damping to reduce the oscillations. The stabilizing fixture was 3D printed, and its fulcrum area and the pickup tool were covered with rubber tubing selected for its damping characteristics.